Estimate reading time: 2 minutes

Altough I haven’t written any post recently, I am spending almost all my free time on the nixie tubes making (or better – trying to make 🙂 ). I am quite busy these days, mostly because of newborn twins ;-)..

I built new spot welder (a tranformer based one) with a pincher and a stem fixture that allows me to make quite nice stems. Now, I am working on glass lathe, completely new design, big thanks to Ron Soyland aka Tubecrafter. There are some photos of my progress on the glass lathe, more photos later..

Left spindle, chuck is being prepared.. Notice the motor and chuck from acu drill and a square rod shaft (will be machined later).

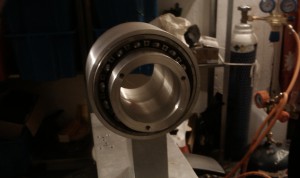

The spindle detail, it consists of a 120mm aluminum housing and two bearings, the inside diameter is 60mm. The housing was machined on a lathe, so perfect concentricity of the bearings was achieved. Notice the gas system in the background, this is used to supply my oxy-gas torches..

One bearing pulled out..

Detail of the inner part of the spindle.

Taken apart.. The rectangular part in the right upper corner will support the spindle on the base..

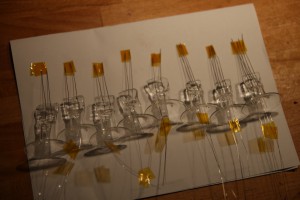

First batch of stems, helium leak tested, half of them is leaking – but I know where I did a mistake..

First try of photo-etching of the digits, 0.1mm stainless steel sheet. It will be much better next time 😉