YEAR: 2019

Client: NASA

In 2019 NASA’s metrology team asked us to build a time-code display precise enough to calibrate their high-speed test-range cameras. We engineered a microsecond-accurate nixie module that can provide accurate time for cameras during rocket and wind-tunnel shots. What began as a simple request quickly became a memorable technical adventure.

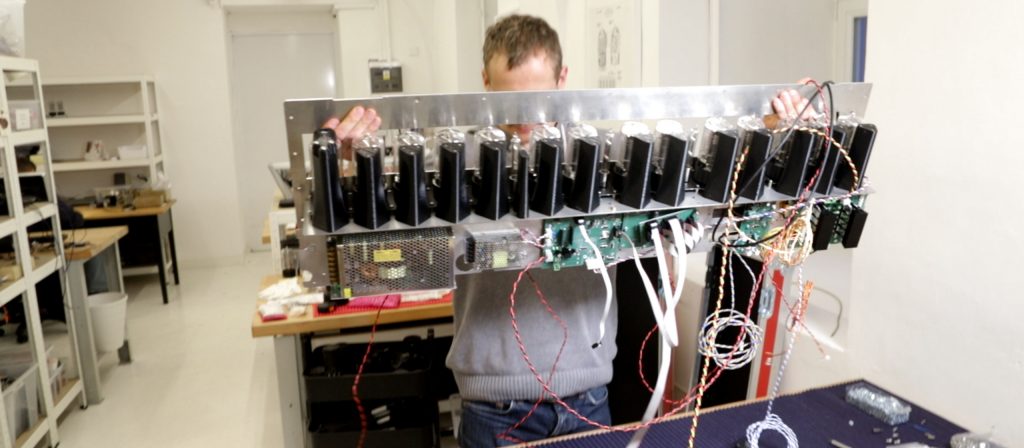

Rolling Up Our Sleeves

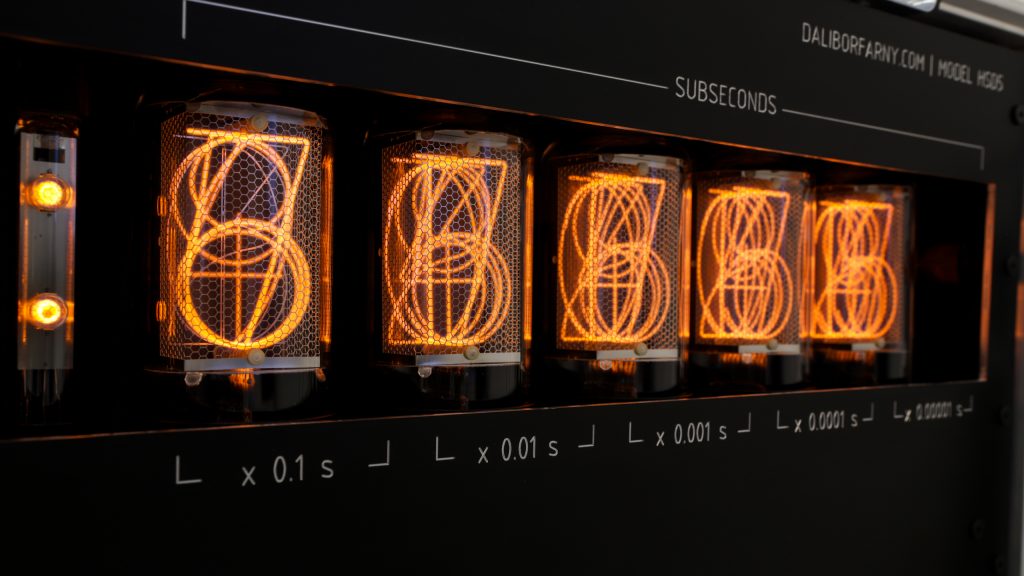

The story started with a simple e-mail from NASA’s metrology team. They needed a time display that their high-speed cameras could photograph to check frame timing—nothing fancy, just accurate down to the last micro-tick. NASA’s laboratory had been using an old Nixie display that marked time in thousandths of a second (0.001 s). Useful, but not enough for today’s ultra-fast cameras. They asked if we could push that resolution to one-ten-thousandth of a second (0.00001 s). We said yes, then got to work—tightening the electronics, testing tube rise times, and finding a way to keep the digits crisp under extreme lighting. No drama, just a lot of bench time and careful tuning to hit that new accuracy target.

NASA came our way for a simple reason: after three decades with no new production, Dalibor Farný’s workshop is the only place still making fresh, reliable Nixie tubes. Could our modern tubes do better than the museum-grade units in their lab? We thought so—but first we had to prove it, one test at a time.

The IRIG timecode is used for transferring timing information from a central time source into a slave equipment such as displays. The implementation of the IRIG required creation of a new, fully analogue part for processing the input IRIG timecode, because our proven electronics arrangement with a digital processor was not fast enough. Despite a few hiccups in development, we still managed to fine-tune this analogue part, so that it has virtually no delays.

Another problem was the interference of signals within the electronics. This is why we had to redesign a significant part of the electronics system.

Within several months, we successfully resolved all the problems. The key person behind the design of the electronics was Sebastian Melzer, an electronics engineer from Germany who was working for us at that time. He played a key role in the whole process.

How fast is a nixie tube?

First we had to answer a simple question: how quick is a Nixie tube, really? In other words, at what frame-rate can we flip a digit before the glow blurs? We took a modified Blub clock to the high-speed-camera lab at Proxis.cz and filmed it under controlled pulses. The footage showed a clean change every 10 microseconds—roughly 100,000 digit swaps per second. That result told us the tubes were easily fast enough for NASA’s calibration rig.

Six months later, we finally shipped the finished display to NASA.

To the human eye only the tenths and hundredths digits stay sharp; everything faster smears into a permanent blur. High-speed cameras are in a different league—at 100 000 fps they read the 1/100 000-second digit without effort, and at two-million frames per second you can actually watch the Nixie glow grow outward in real time the instant a digit fires.

Lessons That Still Pay Off

Those timing tests weren’t a one-off. Now we know exactly how quickly a Nixie can ignite and extinguish, and we use that data in every new project. The big H-tube, for example, borrows the same timing curves to create smooth start-up and fade-out animations.

A video from behind the scenes: