Estimate reading time: 3 minutes

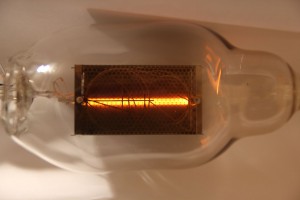

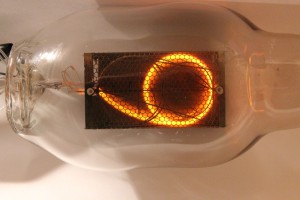

I experienced big success today. I sealed first really working nixie tube (or nixie retort ;-). I surprisingly didn’t forget to do any individual step in the making process and ended up with a tube that by far exceeded my expectations.

I tested the tube carefully on the helium leak detector several times, I also checked all the vacuum system, gass filling manifold and gas connectors. I found one small leak on the teflon washer on one of the needle valves (for neon filling) – repaired – and one on the connector to neon bottle – placed a new o-ring. I pumped down all the vacuum system for several hours, gass filling manifold included. I then rinsed both gas branches with gases to get rid of remaining air, closed both needle valves and made a overpressure in those branches so that no air would get in. It turned up that this step was critical for gas purity.

The tube was baked out to 410C (then it broke down, should go to 480C) and then it was filled with neon and argon (5×10-2 torr of argon accorging to thermocouple – very inaccurate value).

Number “0” is not working as the wire sticking out of the tube broke off 🙁 Also the stainless steel assembly inside is attacked by something that made it “rust” 🙁 I don’t know what.. The tube has so strange shape because I didnt have a tubing of so large diameter, so I had to blow it from smaller one..

The most important thing is that I achieved values of striking voltage that are almost like industry made tubes! That is the most important thing for me!

Striking voltage:

1 – 139V

2 – 136V

3 – 141V

4 – 140V

5 – 131V

6 – 149V

7 – 126V

8 – 124V

9 – 136V